What are THE BEST Hard Yards GRIP sockS for me in 2024?

It’s time for an update on the Hard Yards grip sock range for 2024.

We get a lot of questions on Instagram about the range however we most frequently hear, ‘I love the look of your grip socks, but I’m not sure which one is best for me, could you guys explain the difference?’.

While we aim to give you the low-down in the shop, sometimes a side-by-side comparison is more helpful!

For reference you can go to the product pages for the all our socks below. I’ll just be focussing on the core range in this run down, but you can find our Limited Edition pieces in the shop here.

Here’s a quick summary breakdown.

The Detail.

1 - The Grip

This is the only aspect that is identical between all our grip socks.

We use the same medical-grade silicone both inside and outside. This ensures that your foot grips the sock and the sock grips your shoe, locking you in as one, giving you maximal stability and power transfer with each and every step.

The grip pattern is unique in that they are ‘offset’.

This means that they alternate inside-outside-inside-outside along the length of the sock (see Fig. 1). This design means that when you step down on the grips, they align into a single row and work together to fully lock you in (see Fig. 2). The extra benefit of this alignment is that they don’t sit on top of each other, which would create uncomfortable pressure points. This design is patent-protected and sets us apart as the best-in-class grip sock on the market! Almost all other grip socks only have 1-layer of grip. You can read more about our collaboration with PremGripp and the grip technology here.

— __ — __ Fig.1 (HY ‘offset’ grips)

— — — — Fig. 2 (HY grips align together when you stand up)

2 - The Weight & Cushioning

The Original 365 Sock

The Original 365 Pro + Trainer socks were created as utility/all-round athletic socks and can therefore be used in any sporting endeavour. It is a mid-weight sock with our standard levels of cushioning added around the toes and heel. To contrast with a ‘generic’ off-the-rack sports sock, the HY OGs are thicker, with more padding, but are not overwhelming and so you can wear your usual shoe size. This is a really nicely balanced sock, with a reassuring feel, keeping you comfortable for as long as you need.

Performance Bowler’s Sock

By contrast, the Performance Bowler’s sock (right bottom ->) was designed specifically to reduce the high impacts felt in the feet and toes of cricket bowlers when they plant their front foot down at the end of the run up. Players were telling us that their toes were hitting the inside of their shoes and some even cut holes in the ends off to prevent injury! To meet this need, we combined our double-sided medical-grade silicone grip with a heavy-gauge cotton fibre, increased the thread count and doubled the level of cushioning over the toe cap and the heel. This means the sock feels much more solid and robust on your feet, but with minimal added weight. The grip eliminates any forward travel and the cushioning keeps things snug and supported. While it was designed for cricket bowlers, we have found that many other athletes, big and small, ladies and gents like to use the Performance Bowler’s sock for these added benefits. To give you something to compare it to that you might have worn before, it is somewhere between a mid-weight general sports sock and a performance hiking sock.

The Original 365 Pro v2.0 sock is somewhere in between. It is based weight-wise on the Original 365 Pro, but does have a bit more padding over the heel and toes to reduce the impact when you are hitting the hard court surface.

3 - Ventilation

To account for the heavier knit of the Performance Bowler’s sock, we designed custom air vents over the top of the foot. This ensures that you get all the added benefits described above, without overheating. The Basketball also benefits from this custom feature.

The Original 365 Pro and Trainer socks have our standard slim vents to keep your feet at the optimum temperature.

4 - Ankle support

You’ll notice that the ankle area is slightly thicker and textured compared to the rest of the sock and has a more defined shape.

At this crucial bio-mechanical point, we’ve added 2 things:

Extra padding to ensure that any pressure points with the tops of your boots or any straps are minimised.

Engineered 3D-twisted honeycomb weave creates a mild compression effect around your ankle joint providing added stability and support. It expands as you mobilise but keeps things nice and snug around the ankle.

The Performance Bowler’s sock has both of these features the full 360-degrees around the ankle joing.

While the Original 365 Pro and Original 365 Pro v2.0 socks keep the front of the ankle open to give an improved range of movement in the joint, with little reduction in ankle support generally.

The Original 365 Trainer sock has no ankle support but does have a tab to keep it from slipping off your foot!

Performance Bowler’s Sock

The Original 365 Pro Sock

The Original 365 Trainer Sock

5 - Aesthetics

Finally, a subtle point.

They do look similar, but you’ll notice that the Performance Bowler’s sock has double the number of ‘track lines’ as the Original 365 to reflect the heavier and more dense knit.

For those of you with a keen eye, you might have even spotted below our internal details at the cuff and the braille markers on the back that help our vision-impaired athletes give their best on the field!

Summary

All our socks were designed for quite different and specific purposes however don’t let the ‘Bowler’s’ part of the name put you off from using them for other sports. We’ve found that some basketball, tennis players and weightlifters love the extra weight of the Performance Bowler’s Sock and reap the benefits on the court! However, if you are unsure where to start, we’d always reccommend the Original 365 Pro Sock v1.0 or v2.0 as your introduction to the Hard Yards grip sock tech.

Whichever you choose, you’ll always get the best in class grip to make sure that every step counts! If you’d like to read more about the tech behind the grip, you can read more here.

SAFETY IN SPORT, THE HARD YARDS WAY - PART 2

I wrote an article back in October last year outlining our methodology for developing and testing our protective sportswear, you can find that here. I spoke about the issues with standardised impact testing, what our approach to this is, when it can be useful and when it is not, and even hinted at our partnership with the Innovation Department at Newcastle University and that we were working closely with them to test our guards to research standards. I’m really pleased to be able to tell you a little more about this project, a Part 2 of 3, and provide an update of where we are at.

Aims

Over the past 6 months, we finally managed to get back into the labs to test our guards and answer 4 key questions.

Do our current guards in stock still hit the mark in terms of protection? An internal quality control check.

To what extent does guard thickness and density influence protective capacity, without sacrificing comfort? Should we consider adjusting these parameters for our next batch?

Does a polycarbonate shell make a difference to impact absorption?

How do Hard Yards guards compare to our competitor’s?

Methods

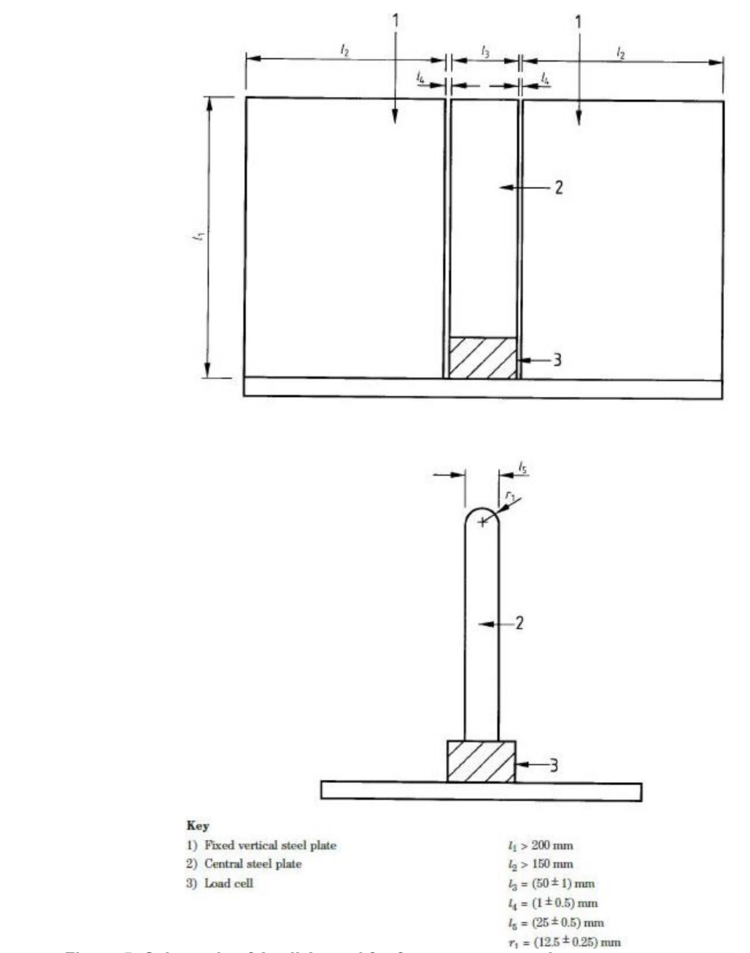

For this testing round (despite my issues with it in Part 1!) it was necessary to control as much about the testing environment and apparatus as possible, and so we chose to replicate the British Standard format. We set up the rig you can see in the right-top image, essentially replicating the British Standard set-up (right-bottom). This ensured that each test would be the same, repeatable and gave a fair representation of what is actually happening in the guards, this optimising our results for both accuracy and precision. The only variable therefore was the guard itself.

Results

So, what about the results, as I know that’s why you are here! I have kept the numbering for our results and discussion sections consistent with each question above →

Our current guards held up as expected to the Level 3 British Standard, this is the highest level for arm guards.

We tested a range of thicknesses from 3mm to 10mm and densities of 20% to 40%. Anything outside of these ranges was either impractically cumbersome, too stiff to conform to the arm, or simply not fit for protective purposes.

There was a definite correlation between guard thickness and protective capacity. It was a repeatable difference of ~500-1000 Newtons of force between the thinnest and thickest guards.

Density however, surprisingly had minimal effect.

Applying a polycarbonate (or similar thermoplastic polymer) shell to the outside of the flexible foam guard does not improve impact protection, and in some tests actually made it less good at absorbing impact force.

Under these testing conditions, there was no statistically significant difference between the Hard Yards guard material and our direct competitors in terms of impact protection for the same thickness of guard. Here is an extract from our testing data.

Discussion

Quality Control

We were really pleased to see that our guards are still meeting the highest testing spec. Clearly, consistency between guards is good, thumbs up to the manufacturers!

Guard thickness

It wasn’t too surprising to see that the thickness of our guards directly correlates with impact protection. Subjectively we felt that this would be the case, but it was still important to bare this out in the data. While this data-set is definitely encouraging, you (and we) should not take this as gospel and that it tells us to how your arm will feel when being hit by a cricket, hockey or lacrosse ball, and you shouldn’t be convinced by anyone who shows you a graph like this and tells you as such. All it shows is that it meets the British Standard and it’s not possible to reasonably extrapolate this data out to real-world sporting conditions or make marketing claims around it. The British Standard does however give us confidence that it reduces impact in a meaningful way and that it does so in a consistent manner without degradation over repeated impacts, but you can’t say what speed of ball it will protect you from or how it will feel, for example. Cricket, hockey and lacrosse balls are all smaller, lighter, and move much faster. Your forearms generally have a more broad impact zone with additional ‘built-in’ cushioning in the form of fat and muscle, and indeed, arms are not fixed objects. All these variables change from person to person, ball to ball and so anyone who tells you that their guard is the best at protecting you from ball-related sporting injuries using this type of data is simply sticking their thumb in the air and hoping you’ll accept the nice graphs as definitive proof that they meet your specific sporting needs. That being said it does provide a degree of scientific confidence and, backed up by anecdotal performance from professional players, we feel confident they do the job, but we’d like to go further.

Guard Density

What did surprise us however is that density did not have much of an effect on impact. Our current guards sit at 43% density and we chose this as it sits right at the higher end without compromising on flexibility and comfort; our hypothesised sweet-spot. While testing densities between 20%-40% showed an observable correlation with impact protection from a raw data perspective, this was statistically non-significant under these testing conditions. In our minds, it would make sense to use the lowest density we can to achieve the necessary impact protection. This prevents material wastage and there is a subjectively noticeable difference to the weight and flexibility of the guard, all good things. In this case, it might be that under these standardised testing conditions, the true difference between 20% and 40% density was not observed, but under more realistic conditions, ie, high-speed impact with a cricket ball this difference might be seen more clearly. At this stage, we’ll continue to use the higher densities until further experimental testing is done.

Polycarbonate - the elephant in the room.

We noticed a while ago some arm guard manufacturers have opted to glue an additional thin polycarbonate (or other thermoplastic polymer) plate to the outside of their guard, aiming to improve protection beyond the standard guard. This is sometimes marketed as a ‘Pro’ version that will do a better job of protecting your arms from impact, targeting pro-game speeds.

Our testing showed with convincing repeatability that adding a polycarbonate plate does not improve the protective capabilities of any of the guards we tested. Some of the tests even showed a reduction in impact absorption.

This was a result we did not expect. I can honestly say that we really did not know if it would actually make a difference or not; our intuition said that a solid piece of polycarbonate should do something positive, but we don’t rely on intuition alone, and that’s precisely why we ran the tests. In some ways, we were quite disappointed as we were keen to potentially implement this into our own line-up of guards however following this testing, clearly this would be futile and without benefit to our athletes.

It’s not entirely clear why this might be happening. With non-Newtonian protective materials, impact force is reduced both by the molecular bonds dynamically strengthening in response to the impact, but also by decelerating the object through compression the material itself. When discussing with Dr Oila at Newcastle University (project supervisor) we felt that the most likely explanation at play is that the polycarbonate does not allow the non-Newtonian material underneath to compress, an action that is required for the guard to effectively dissipate the impact force over its full area.

Regardless of the explanation for why this may be occurring at the material science level, we can be confident that a polycarbonate shell is not beneficial and it is most likely only providing a placebo effect ie, it subjectively feels more solid and people may therefore feel it will provide better protection, even if this is not true in reality.

Hard Yards vs The World!

Last but not least, we were both pleased and (ever so slightly!) disappointed to see that of all arm guard brands tested that use a non-Newtonian material, protective capacity was largely the same when we controlled for guard thickness. The traditional guards (those using a HDPE or very thick spongy foam) did not fair well enough to include in the charts above.

Clearly, we’d love to tell you our guard material is the best in the market, but between the 2 guards that use a non-Newtonian material, they both protect to a very similar degree, likely imperceptible and probably not significantly different from a clinical perspective. While this is interesting in itself, it informs a lot more about how you should choose which brand to go with when purchasing a new arm guard, ie, don’t worry about the guard itself!

If optimised protection, flexibility and comfort is key, and you also want the option to change the level of protection, or to change the sweatband colour to suit your needs at the crease then we would recommend our patented High Impact Protective Guard as the best overall guard on the market at present!

However, if you absolutely need to have that subjective ‘feeling’ of a solid guard, we’d first urge you to give our guard a try, but there are some solid guards out there that do a comparable job at protecting your arm. Bear in mind however that it is just a feeling and carries no additional impact protection over their soft shell version, you are simply paying extra for the feeling and the overall comfort/breathability will be less good! In addition, other arm guards seal their guards into the sweatbands, so you won’t be able to adjust the protection level or change the colour so it will cost you far more in the long run.

Recommendations & Future work

Don’ buy into the marketing around ‘Pro’ versions with an added solid polycarbonate polycarbonate plate, unless you simply prefer the subjective feeling of a solid guard.

Overall, the Hard Yards High Impact Protective Guard offers the greatest overall benefit to our athletes’ performance in terms of flexibility, comfort and the ability to swap to different guard thicknesses or sweatband colours easily. Our patented design also means that if you want to upgrade, or replace a worn out component, you don’t need to buy a whole new set, you can simply buy an individual piece!

Moving forwards, we’ll be testing our guards further under more realistic match-play conditions using a custom rig and bowling machine. This will be to understand how the various differences in the data play at higher, more realistic speeds. Standby for Part 3!

Until next time!

GOING FURTHER FOR positive impact

For athletes all around the world, playing sport means more than simply winning or losing.

While we regularly compete upon grass, ground, sand, or sea, it is very clear that we, the sports community, want to look after the planet we love to play sport on.

When we sat down together to discuss the idea that would become Hard Yards, we decided that making a positive impact on the health of our environment would be one of our core values. From day 1, we were conscious that we wanted to make it clear what this actually means, and ensure that we are transparent with what we do now and with our plans for the future. Greenwashing is becoming all too commonplace in the sportswear industry and misleading customers only hinders making a genuine positive impact.

Earth Day 2022 has just passed and it gave us some time to reflect on what transparency means in this regard; an openness about where we are, and accountability for where we are heading in the future. Our journey has only just begun, the foundations have been laid, and we’d like to share this journey with you as we grow the Hard Yards community together.

2021 Impact Report - Fundamentals First.

Support Local Manufacture - With our HQ in Leicestershire, we strive to support our local manufacturing community where we can. Doing so helps us to reduce the travel mileage (land, air, and sea) of our products and having local access to our factories also means that we can physically see how our products are made, what materials go into them and how they are processed. Currently, the only aspect manufactured outside Leicester is the raw material for our High-Impact Guard, which is made in Portugal.

Product Lifecycle - We know that no product will function as intended indefinitely and so we seek to work towards a better lifecycle for our kit. At manufacture, we use natural yarns such as organically-grown cotton and mix in synthetic fibres when the processing cost vs longevity gain is balanced or positive for the latter. In use, we strive to make products that will serve you on the pitch season after season and so we opt for more durable yarns and weaves that help your Hard Yards kit last longer.

Packaging - We committed early to a minimum standard. This standard is making our packaging from 100% FSC recycled card stock that is itself 100% recyclable; even down to the sticky label that keeps the box closed.

Active Positive Impact - For every product we have delivered, we have planted mangrove trees (>1200 so far!) to restore carbon-sink zones around the world and support local villagers with a stable income. To find out more, this journal article from Chris will explain in more detail.

Steps for 2022

Local Manufacture - As our product-line expands, we’re maintaining our local manufacture commitment and looking for ways to bring this to 100% across the range.

Product Lifecycle - Cotton is a staple yarn for us, however we’re bringing organic varieties and recycled synthetics to this years developments as well as investigating alternative plant-based fibres such as bamboo, merino and rayon-based yarns as potential improvements.

Packaging - We’re introducing the ‘Get Naked’ campaign, where we offer the option to reduce the amount of packaging that we use for your order. You can read more about this campaign here. Further to this, we looking to make more of our packaging not only recyclable, but also compostable and we are looking at a variety of plant and fungus-based options for this.

Active Impact - This year, we’re aiming to hit or next milestone of 5000 trees planted with over 50,000kg of carbon sequestered out of the atmosphere by our reforestation activities.

In the spirit of putting in the ‘Hard Yards’ we acknowledged that we would never be perfect at launch, however we have committed to working towards making a greater positive impact year after year. We’re taking those small steps forward, adding those marginal gains up and every year we’ll share with you how we and the Hard Yards community are making a difference beyond our immediate reach.

Which Hard Yards grip sock should I use?

We get a lot of questions over on Instagram about the Hard Yards range however we most frequently hear, ‘I love the look of your grip socks, but I’m not sure which one is best for me, could you guys explain the difference?’.

While we aim to give you the low-down in the shop, sometimes a few more words are needed, so I’ll lay it all out here.

For reference you can go to the product pages for the Original 365 and Performance Bowler’s socks here.

1 - The Grip

This is the only aspect that is identical between the socks.

We use the same medical grade silicone both inside and outside. This ensures that your foot grips the sock, and the sock grips your shoe, giving you maximal stability and power transfer with each and every step.

Taking things a step further, you will find that our grips are ‘offset’.

This means that they alternate inside-outside-inside-outside along the length of the sock (see Fig. 1). This design means that when you step down on the grips, they align into a single row and work together to fully lock you in (see Fig. 2). The extra benefit of this alignment is that they don’t sit on top of each other, which would create uncomfortable pressure points. This design is patent-protected and sets us apart as the best-in-class grip sock on the market!

— __ — __ Fig.1 (Hard Yards ‘offset’ grips)

— — — — Fig. 2 (Hard Yards grips align together when you stand up)

They can feel a little strange when you first put them on. However, once you warm up and the silicone reaches body temperature, you’ll forget they are even there, but you’ll notice the impact on your game!

2 - The Weight & Cushioning

The Original 365 sock as created as a utility sock and can be used in any sporting endeavour. It is a mid-weight sock with our standard levels of cushioning around the toes and heel, but it has more substance than you would find on a generic sports sock. This is a really nicely balanced sock, with a reassuring feel, keeping you comfortable for as long as you need.

By contrast, the Performance Bowler’s sock (right bottom ->) was designed specifically to reduce the high impacts felt in the feet and toes of cricket bowlers when they plant their front foot down at the end of the run up. Players were telling us that their toes were hitting the inside of their shoes and some even cut holes in the ends off to prevent injury! To meet this need, we combined our double-sided medical-grade silicone grip with a heavy-gauge cotton fibre, increased the thread count and doubled the level of cushioning over the toe cap and the heel. This means the sock feels much more solid and robust on your feet, but with minimal added weight. The grip eliminates any forward travel and the cushioning keeps things snug and supported. While it was designed for cricket bowlers, we have found that many other athletes, big and small, ladies and gents like to use the Performance Bowler’s sock for these added benefits. To give you something to compare it to that you might have worn before, it is somewhere between a mid-weight general sports sock and a performance hiking sock.

3 - Ventilation

Now, to account for the heavier knit of the Performance Bowler’s sock (right bottom ->), we designed custom air vents over the top of the foot. This ensures that you get all the added benefits described above, without overheating.

The Original 365 sock (right top ->) has our standard slim vents to keep your feet at the optimum temperature.

The Original 365 Sock

Performance Bowler’s Sock

4 - Ankle support

You’ll notice that the ankle area is slightly thicker and textured compared to the rest of the sock and has a more defined shape.

At this crucial bio-mechanical point, we’ve added 2 things:

Extra padding to ensure that any pressure points with the tops of your boots or any straps are minimised.

An engineered 3D-twisted honeycomb weave creates a mild compression effect around your ankle joint providing added stability and support. It expands as you mobilise but keeps things nice and snug around the ankle.

The Performance Bowler’s sock has both of these features the full 360-degrees around the ankle.

While the Original 365 sock leaves the front open for better and an even greater range of movement in the joint.

The Original 365 Sock

Performance Bowler’s Sock

5 - Aesthetics

Finally, a subtle point.

They do look similar, but you’ll notice that the Performance Bowler’s sock has double the number of ‘track lines’ as the Original 365 to reflect the heavier and more dense knit.

For those of you with a keen eye, you might have even spotted below our internal details at the cuff and the braille markers on the back that help our vision-impaired athletes give their best on the field!

Summary

These two socks were designed for quite different purposes however don’t let the ‘Bowler’s’ part of the name put you off from using them for other sports. We’ve found that basketball and squash players as well as weightlifters love the extra weight of the Performance Bowler’s Sock and reap the benefits on the court! However, if you are unsure where to start, we’d always reccommend the Original 365 Sock as your introduction to the Hard Yards tech.

Whichever you choose, you’ll always get the best in class grip to make sure that every step counts! If you’d like to read more about the tech behind the grip, you can read more here.

Safety in Sport, The Hard yards way - Part 1

Traditionally, protective wear in hard-ball sports such as cricket, field hockey and lacrosse has largely been an afterthought for sportswear brands who were keen to capitalise on the high-margin items such as cricket bats and helmets. Usually you’ll find a thick spongy piece of foam affixed to the arm with a pair of bulky velcro straps that (attempt to) keep it in place; not a very slick solution!

With advancements in materials science and clever 3D-fabric manufacturing techniques, things have begun to slim down. Subsequently, we find now that there are a couple of good simple solutions available to athletes on the market at present. However all (with the exception of our own design!) do not have an interchangeable construction and miss the mark with the smaller details that make a big difference to overall enjoyment when wearing.

The second issue arises from the regulation and standardisation of testing and indeed the precise way that the protective materials are tested is an issue in and of itself.

Regulation & Standards - This has been historically not-so-well regulated however in recent times, new legislation has come in to play and now sports PPE is beginning to see a base standardisation for quality and testing which is certainly progress.

Testing - As part of basic regulation, testing is often employed however, to standardise the testing of something means more often than not to test the object under very tightly controlled conditions using nicely rounded numbers in an environment that is very much removed from where the PPE is to be used.

In the case of protective wear this almost exclusively means that it is a ‘drop-test’ of some sort, ie, where a metal ball or plate of a pre-specified size and mass is dropped from a specified height onto the material being tested which rests upon an anvil of a specified shape and size. Now, you might feel that this is the best or only (or indeed a good!) way to test sports PPE, and to be fair it does make it easier to compare one type of protective material with another, but only under these particular circumstances.

Unfortunately, the circumstances of standardised testing are so far removed from the realities of the conditions that you, the athlete will face (such as a +90mph cricket ball) that any conclusions drawn are essentially meaningless in the real-world context of what you (the athlete!) will actually experience on the field. Furthermore, it would be inappropriate to draw any particularly meaningful clinical conclusions from a medical perspective from such data.

To illustrate, the British Standard for testing a protective arm guard is BS EN 6183-3:2000-3.2.2 and to the right is an extract diagram of the testing set-up; how inspiring!

In this test, the protective material is applied to the metal plate above and dropped onto the metal anvil below to achieve an impact force of 10J (joules).

Now the output from such a test would be a number that tells you how much of the original impact force (10J) is measured on the other side of the test material. To meet the level 3 standard (which is the highest for cricket PPE excluding gloves and helmets) it would need to demonstrate a force measurement of 4kN or less and we are pleased to see that our material does favourably and better than common alternatives (below).

Force measured against 10J impact test

This is all very pleasant, and looks very positive on the surface but let me ask you:

Do you know what a 10J impact feels like?

Could you tell me the difference between 35kN and 3kN? What about 8kN and 3kN; is this the difference between breaking your arm and not, or simply the difference between no pain and a mildly painful bruise to the wrist?

No, I’ve no idea either.

As a medical doctor I deal with scientific data on a daily basis however often I am asked to interpret clinical data presented and understand if the conclusions drawn are actually relevant to my patients or just look significant from the raw numbers.

This is where the Hard Yards philosophy of doing more for our athletes comes in.

We know that our protective guards hold up in standardised tests (although I hope I have changed your view of when it is appropriate to use these!).

We know anecdotally from our pro and amateur-testers that when a high-speed bouncer wallops you in the forearm, you barely feel it. But this is not good enough quality of evidence from our point of view.

We want to be completely confident that our kit will do the job it is designed to do. Not only transmit less than 4kN on a drop-test, but make a clinically relevant difference by preventing fractures, reducing game-altering pain and keeping you focussed on the job at hand.

That is why we are currently partnering with Newcastle University over the next 3 months to test our protection in as real-world conditions as we can recreate both in the lab and in the nets at high speeds. Speeds beyond what you would expect to face at the crease, on the hockey astroturf, or on the lacrosse field.

We also know that because of the molecular properties of our non-Newtonian-based material, the impact absorbing capabilities increase as the force of the impact increases. However we don’t know what the force-curve looks like, or what the true upper limits are. So, we’re going to push our protection to its breaking point so that when you wear our kit you know it does what we say it can and you can concentrate on doing what you do best!

I’ll be writing Part B of this article when we have the report available from the Newcastle University project team later this year. And, if it doesn’t stand up to the testing, we’ll be back to the drawing board the next day.

That’s the Hard Yards way!